Advanced Casting Solutions for Diverse Industries

We utilize chemically bonded sand molding to create durable, high-precision castings for a variety of applications. Our process ensures consistency, strength, and adaptability for both prototype and low-volume production.

See What We Offer

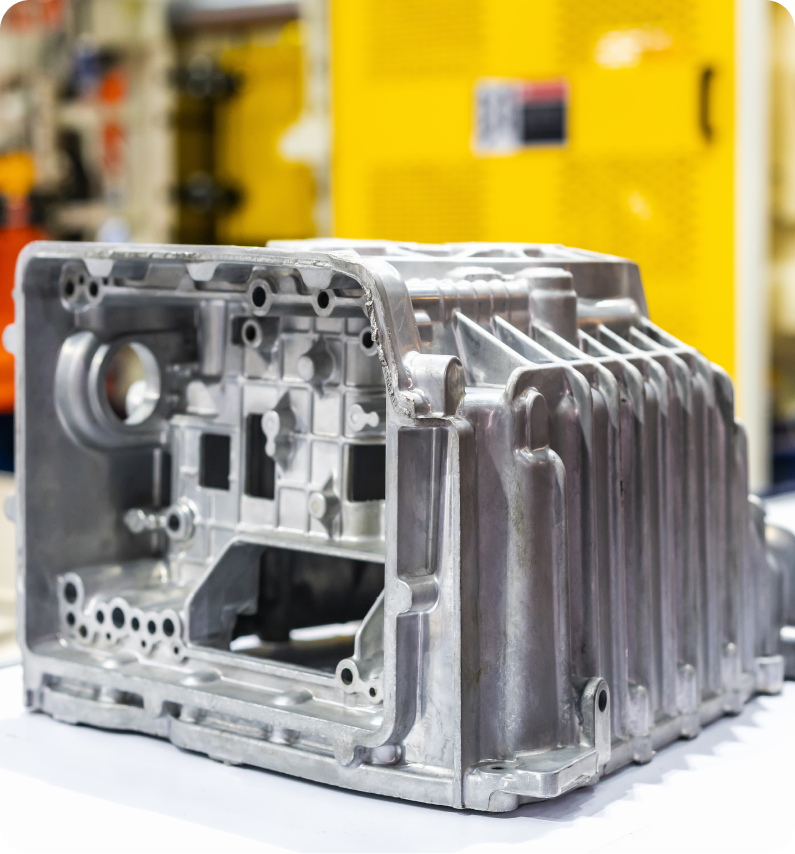

Aluminum Casting

We use a chemically bonded sand molding technique to produce castings with high dimensional accuracy and superior surface finishes. Our expertise includes working with aluminum alloys such as 356, 355, 319, 535, and 206 to meet diverse industry requirements.

Secondary Operations

Beyond casting, we offer certified in-house heat treatment, age treatment, sandblasting, grinding, and vibratory deburring. For enhanced quality assurance, optional mechanical and chemical testing, including X-ray inspections, are available.

Prototype Development

Our prototype casting capabilities help manufacturers refine designs, eliminate errors, and accelerate time-to-market. We provide precision-driven solutions to support seamless product development and validation.

Custom Solutions for Your Casting Needs

We deliver precision, durability, and efficiency for every project. Get in touch today to discuss your casting requirements.